Finish

The set of operations performed on the stone’s surface, each of which has its unique attraction, is called finish.

In this article, we are going to discuss different types of stone surface finishes.

Polished Natural Stone Finish

The most common practice in stone finishing is to make the stone’s surface polished and shiny, which is provided by polishing bits on the stone’s surface. There are different methods of grinding or polishing considering different stones, and the surface of the stone is polished and ground only with designed grinding bits.

Polished Natural Stone Finish

Honed Finish

In honed finishing, the surface of the stone is uniform but has a matte appearance and the light is not reflected from its surface. The stone’s surface is polished, but considering the special finishing method, it becomes matte, giving it a special beauty. It is used to beautify walls of lobbies, stores, etc.

Leather Finish Stone

Leather finishing is a kind of antique work whose purpose is to create an old feeling on the surface of the stone. In the leathering method, instead of using ordinary bits, some bits are used that have a greater impact on the weaknesses of the stone. Those parts will face more grinding which causes ups and downs on the surface of the stone. In leather finishing, the holes and porosity of the stone are not filled, and its surface becomes velvety with ups and downs, and it will be a little shiny.

Leather Finish Stone

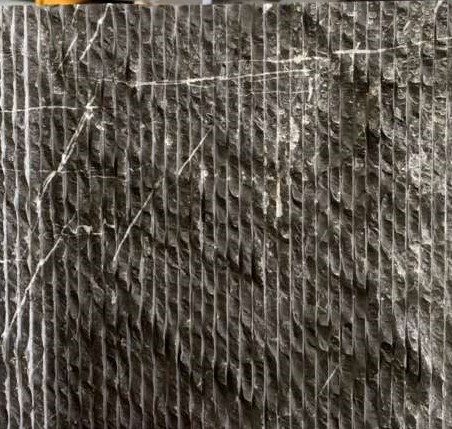

Bush-hammered Finish

In this type of finishing, significant changes are made to the appearance of the stone. Also, deep porosity will be applied to the surface of the stone, so that its surface becomes uneven, rough, and regularly needle-like. The main reason for stone finishing in the form of bush-hammered is to prevent slipping and sliding of the stone. Therefore, this feature has caused this kind of finishing to be used more in environments such as parking lot floors, yard floors, and mainly as paving in open spaces. Bush-hammered finishing is used on stones with high resistance and strength, such as pietra gray marble.

Bush-hammered Finish

Flamed Finish

In this type of finishing, setting fire to the surface of the stone will cause the surface to become rough, and in some granite stones, it gives the stone a special beauty. This method is mostly used on granite stone to prevent slipping on the pavement.

Flamed Finish (White salt & pepper)

Sandblasted Stone Finish

This process causes the surface of the stone to be slightly roughened by sand being sprinkled by the wind (high pressure) on the surface of the stone.

Sandblasted Stone Finish

Sandblasted-Brushed Stone Finish

This process combines two finishes, Sandblasted, and leather, which give the stone’s surface a special state, i.e. hollow, along with a velvety state.

Bush-hammered-Brushed Finish

This finish is a combination of two finishes, first, the stone is Bush-hammered and then it is leathered by special bits of stone. This process is considered one of the most special finishes and is mostly done for marble and travertine stones.

Bush-hammered-Brushed

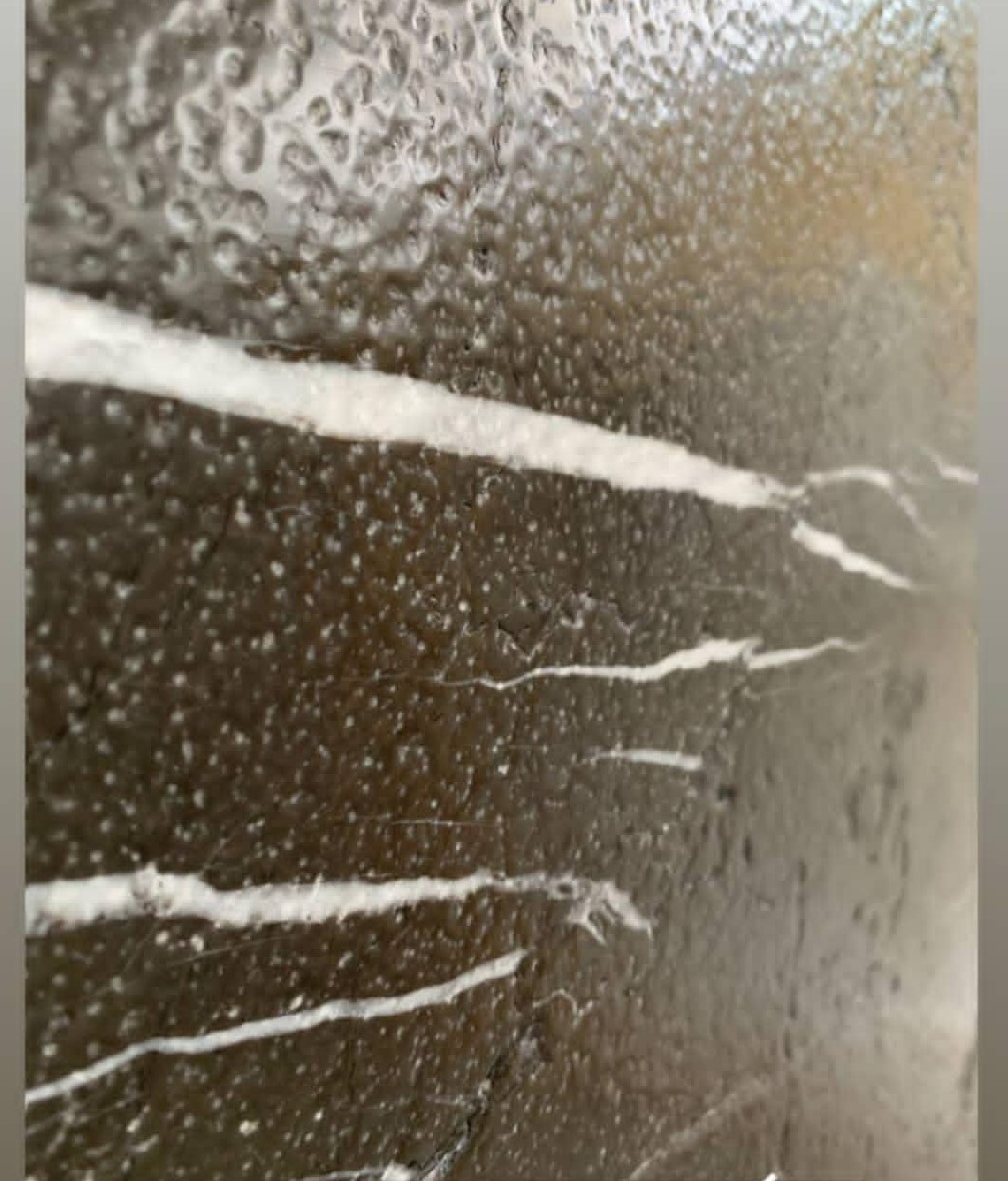

Rigato Finish

This finish is done by a special device as irregular grooves are applied to the surface of the stone. These stones can be used in the lobby, exterior areas, parking lot walls, etc.

Rigato finish (lava stone)

Rigato finish (Iskato stone)

Rigato finish (Picasso Green Granite)

Groove Finish

This finish is done by a special machine as regular grooves with a distance of about 3 to 5 cm are applied on the surface of the stone, which is mostly used for stepping stones.

Groove Finish

Tumble Finish

This finishing is done by several machines. So that grinding the stones on each other causes the sharp corners of the stone to be disappeared and it provides an ancient appearance.

Cut broken Finish

In this finish, the surface of the stone is broken after grooving, and the state of fracture and ups and downs can be seen on its surface.

Cut broken finish

Tooled Finish Stone

In ancient times, scratches were created on the surface of the stone with a chipping hammer, the purpose of which was to prevent slipping.

Tooled Finish(Pietra Gray Marble)

Cut-Hammered Finish

After the broken cut finishing, bush-hammered finishing will be also done. In this method, the stone has a softer surface than in cut broken type.

MUSHROOM Finish Stone

This covering for marble, travertine, and granite is very similar to a broken or divided piece using a cutting machine, but with more ridges and eminences.

Acid-Washed

In this process, the surface of the stone is washed with acid and becomes rough.

Split Face

In this process, the stones are cut by a special cutting machine with dimensions of 5×30. The stones in this process have a rough surface. This process is used for exterior or interior and even TV walls. As you can see in the photo below, this facade is used on the exterior and the entrance door of the building.

Split Face Finish

Each of these products has different uses.

Thank you for staying with the TABA STONE article until the end.For more information contact TABA STONE Group. We also invite you to take a tour of our Instagram page. you will find a lot of new offers on the page.